|

|

|

| TherMonitor™ With Built-In Linearizer

Linear Laboraties line of Non-Contact Infrared Sensors are designed to provide accurate, continous temperature measurement in a wide variety of manufacturing settings. The TM-Series infrared thermometers work by collecting the infrared radiation (heat) from a remote object and focusing it on a detector. The infrared detector converts the signal to produce a 4-20 mA linearized output which is transmitted to controllers, indicators or computers

|

|

|

TM-Series Unique Design

The TM-Series Non-Contact Infrared Sensors are housed in small sealed units to provide years of accurate, reliable, trouble-free operation.

Stability is assured through the use of state-of-the-art amplifiers and infrared detectors. Since there are no moving parts to wear or degrade, TM-Series Non-Contact Infrared Sensors last indefinately. Long-term accuracy is achieved with a solid-state auto-zeroed amplifier and a unique thermal design which eliminates drift due to changes in ambient temperature.. Repeatability of a measurement is assured by the digitally set emittance.

Each TM-Series Non-Contact Infrared Sensors

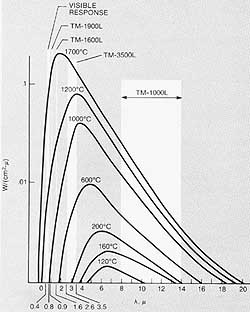

model operates in a specific atmospheric "window" so the readings are independent of distance and not influenced by the presence of water vapor and carbon dioxed in the measurement path. For example, the TM-1000L employs an 8-14 micron spectral filter to minimize interference from short-wavelength radiant heat sources such as quartz lamps. This long-wavelength response also eliminates the effect of target color.

|

|

Applications

TM-Series thermometers are ideally suited for moving, inaccessible or fragile targets. Typical applications include paper processing and printing, textile manufacturing and finishing, rubber and plastic processing and virtually any process where product temperature is a critical factor.

For small or distant hot targets, the TM-Series offers models with an integral non-parallax sight. These instruments can be focussed on targets from 18 inches (45 cm) to infinity simply by rotating the lens barrel. For very small targets at short distances, special optics can be provided. When very bright targets are viewed, the eyepiece can be rotated to darken the visual image for eye comfort.

|

|

Installation

Wiring is easy since the current transmitter design requires only two wires between the TM unit and the device it drives. The wires can be pulled through a conduit easily and attached to the TM unit barrier strip. No special connectors are required. Since the TM is a current transmitter, it can be mounted any distance from its associated indicator, controller, data logger, or computer interface. Integral RFI noise protection circuits help to ensure that a reliable signal will be transmitted without additional electrical filtering.

Because the TM-Series Non-Contact Infrared Sensors are non-contact, they can be mounted at a convenient distance from the product to be measured. As long as the product size is as large as the area viewed by the thermometer, measurements are not dependent on the distance to the product. The TM-Series optics, sensors and circuitry are sealed in a rugged aluminum housing completely protected from dust, dirt and moisture. Because there are no motors, choppers or other moving parts, these units can be installed in harsh thermal or mechanical environments. TM thermometers will operate in ambient temperatures from 10°C to 55°C (50°F to 131°F) without cooling. A water cooling jacket is available for environmental temperatures from 10°C to 180°C (50°F to 350°F).

|

|

|

WC-1000 Water Cooled Housing. The WC-1000 is a welded aluminum housing for all TM-Series heads for use in ambient temperatures from 130°F to 350°F (55°C to 180°C). The enclosure is complete with ¼ NPT fittings and two ¼-20 mounting holes.

Dimensions: 3.45" x 3.7" x 5.6" Long 88mm x 94mm x 142mm

Mounting: Two ¼-20 and Two M10 x 1.5 Thread

Water Connections: 1/4 NPT

AP-1000 Air Purge Fitting. The AP-1000 is used with all TM-Series sensing heads where dusty environments are encountered. Low pressure instrument air can be directed across the instrument lens to prevent accumulation of dust.

Dimensions: 2.5" x 2.75" x 2.5" Long 64mm x 70mm x 64mm

Mounting: Four 1/4" dia. holes matching TM heads

Airpurge Connection: 1/8 NPT

|

|

|